Drop Testing System

Drop testing determines the ability of a package to withstand the rigors of handling by people and machinery in the distribution environment. AEC’s Drop Testing Systems are available to thoroughly examine the effectiveness of package cushioning and its ability to protect your product, closures, and other critical design attributes when exposed to all possible drop test environments. The precision systems with Pneumatic Arm and Tridentate types provide versatile applications with different drop heights and drop arms even for large-size packages.

Features of AEC Drop Testing Systems

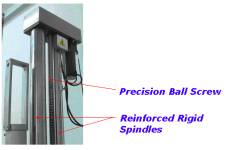

- Fast motion of drop arm precisely driven by servo ball screw with reinforced rigid spindles.

- Drop arm designed with lightweight, good strength, reliability, and positioning accuracy.

- Patent drop arm with two-step fast lowering mechanism to naturally drop the packages and prevents inadvertent drops due to failure supply of air or electricity.

- Patent Oil Pressure Absorber absorbs more than 90% of motion energy to prevent vibration of the structure from fast lowering of drop arm.

- Easy installation with reinforced base plate without destroying the floor and saving space for drop testing.

- Fast raise speed of 2cm/sec with slow adjustment speed of 0.5cm/sec.

- Maximum loading capacity is 100kg.

- Minimum dropping height is 300mm.

|

Specifications of Drop Testing Systems

|

||||

|

Model

|

128A

|

128DA

|

AS

|

DT2

|

|

Type

|

Pneumatic Arm

|

Pneumatic Arm

|

Pneumatic Arm

|

Tridentate

|

|

Dropping Platform (cm)

|

85x156

120x156 120x180 150x156 Customer Spec. |

85x156

120x156 120x180 150x156 Customer Spec. |

95x110

|

130x153

|

|

Testing Height (cm)

|

30 ~ 130

30 ~ 180 30 ~ 200 |

30 ~ 130

30 ~ 180 30 ~ 200 |

31 ~ 130

|

0 ~ 80

|

|

Max. Payload (kg)

|

60

|

60

|

60

|

300

|

|

Absorber

|

Oil Pressure

|

Oil Pressure

|

Rubber

|

-

|

|

Height Control

|

Manual

|

Manual / Auto

|

Manual

|

Manual

|

|

Elevator

|

Precision Ball Screw Driven by Servo Motor

|

Precision Ball Screw Driven by Servo Motor

|

Belt Driven by Motor

|

Belt Driven by Motor

|

|

Height of Machine (cm)

|

225

275 295 |

225

275 295 |

260

|

150

|

|

Weight (kg)

|

350

420 450 |

350

420 450 |

300

|

1500

|

|

Power Requirement

|

220 V / 2 A

|

|||

|

Pneumatic Pressure (kg/cm2)

|

6

|

|||

|

Measurement System

|

All Types

|

|||

|

Specifications subject to change without notice

|

||||