可靠度工程的專業團隊

在全球運籌以及分工整合的趨勢下,低成本的產品不難在市場上獲得,價格競爭不再是主要的方式,因此,如何加快產品的上市速度以及確保產品的品質和高可靠度,就成為各先進企業所積極爭取的關鍵優勢競爭力。

Drop testing determines the ability of a package to withstand the rigors of handling by people and machinery in the distribution environment. AEC’s Drop Testing Systems are available to thoroughly examine the effectiveness of package cushioning and its ability to protect your product, closures, and other critical design attributes when exposed to all possible drop test environments. The precision systems with Pneumatic Arm and Tridentate types provide versatile applications with different drop heights and drop arms even for large-size packages.

Features of AEC Drop Testing Systems

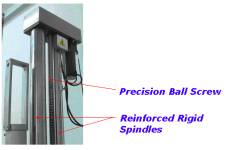

- Fast motion of drop arm precisely driven by servo ball screw with reinforced rigid spindles.

- Drop arm designed with lightweight, good strength, reliability, and positioning accuracy.

- Patent drop arm with two-step fast lowering mechanism to naturally drop the packages and prevents inadvertent drops due to failure supply of air or electricity.

- Patent Oil Pressure Absorber absorbs more than 90% of motion energy to prevent vibration of the structure from fast lowering of drop arm.

- Easy installation with reinforced base plate without destroying the floor and saving space for drop testing.

- Fast raise speed of 2cm/sec with slow adjustment speed of 0.5cm/sec.

- Maximum loading capacity is 100kg.

- Minimum dropping height is 300mm.

|

Specifications of Drop Testing Systems

|

||||

|

Model

|

128A

|

128DA

|

AS

|

DT2

|

|

Type

|

Pneumatic Arm

|

Pneumatic Arm

|

Pneumatic Arm

|

Tridentate

|

|

Dropping Platform (cm)

|

85x156

120x156 120x180 150x156 Customer Spec. |

85x156

120x156 120x180 150x156 Customer Spec. |

95x110

|

130x153

|

|

Testing Height (cm)

|

30 ~ 130

30 ~ 180 30 ~ 200 |

30 ~ 130

30 ~ 180 30 ~ 200 |

31 ~ 130

|

0 ~ 80

|

|

Max. Payload (kg)

|

60

|

60

|

60

|

300

|

|

Absorber

|

Oil Pressure

|

Oil Pressure

|

Rubber

|

-

|

|

Height Control

|

Manual

|

Manual / Auto

|

Manual

|

Manual

|

|

Elevator

|

Precision Ball Screw Driven by Servo Motor

|

Precision Ball Screw Driven by Servo Motor

|

Belt Driven by Motor

|

Belt Driven by Motor

|

|

Height of Machine (cm)

|

225

275 295 |

225

275 295 |

260

|

150

|

|

Weight (kg)

|

350

420 450 |

350

420 450 |

300

|

1500

|

|

Power Requirement

|

220 V / 2 A

|

|||

|

Pneumatic Pressure (kg/cm2)

|

6

|

|||

|

Measurement System

|

All Types

|

|||

|

Specifications subject to change without notice

|

||||

AEC’s Free-Fall Type Shock Testers are designed to accurately simulate real environment of classical shock waves by dropping a shock table supported by 4 precision guide rods. High stiffness and lightweight of Shock table is precisely driven by linear ball screw with servomotor that provides fast, quiet, and safely motion with minimum adjustment of 1 mm. Acceleration levels are generated by table drop height while time duration is a function of the programmer provided, include half-sine, saw tooth and square wave pulses. Every machine is supplied with patent brakes to prevent repeated impacts and incorporate a hydraulic buffer and vibration isolator to isolate the shock from the floor

- Patent electromagnetic breaks allow precisely shock impact and prevent inadvertent drops due to failure supply of air or electricity.

- Fully digital control system displays real-time impact status up to 4 channels simultaneously

- User-friendly interface with pop-up menu and interactive operation.

- Fast change of waveform including half-sine, saw tooth and square wave pulses.

Specifications of Free-Fall Type Shock Testers

Model

DP-1200-25-SDP-1200-25DP-1200-45DP-1200-60DP-1200-80DP-1200-100Size of Table (mm2)250x250250x250450x450600x600800x8001000x1000Weight of Table (Kg)3636100200320410Material of TableAl-Ma Alloy / Ma(Light Table)WaveformHalf Sine,Square,Saw ToothMax. Payload (Kg)35505090105200Min. Pulse Duration (ms)112Type Ⅰ- 2

Type Ⅱ- 333Max. Acceleration (g)650650500350300300Max.Test Height(mm)Type Ⅰ- 1800

Type Ⅱ- 1000Type Ⅰ- 1800

Type Ⅱ- 10001800180018001800Max. Change Rate of Velocity(m/ss)7.4 / 3.47.4 / 3.47.47.47.47.4Size of Machine L x D x H(cm)Ⅰ- 85 x 60 x 310

Ⅱ- 85 x 60 x 210Ⅰ- 85 x 60 x 310

Ⅱ- 85 x 60 x 210105 x 75 x 310145 x 90 x 310145 x 110 x 310145 x 80 x 310Weight of Machine (Kg)100010001600300038004800Light MechanismLinear Ball Screw Driven by Servo MotorPower Reruirement220V / 30APnenmatic Pressure(Kg/cm2)6~8Specifications subject to change without notice